When it comes to precision machining, selecting the right external cylindrical grinder can significantly affect efficiency, accuracy, and overall productivity. The choice between a manual grinder and a CNC (Computer Numerical Control) grinder depends on various factors such as the complexity of workpieces, production volume, budget, and operator expertise. This article provides a comprehensive comparison of manual and CNC external cylindrical grinders, helping you determine which option best suits your machining needs.

Understanding the External Cylindrical Grinder

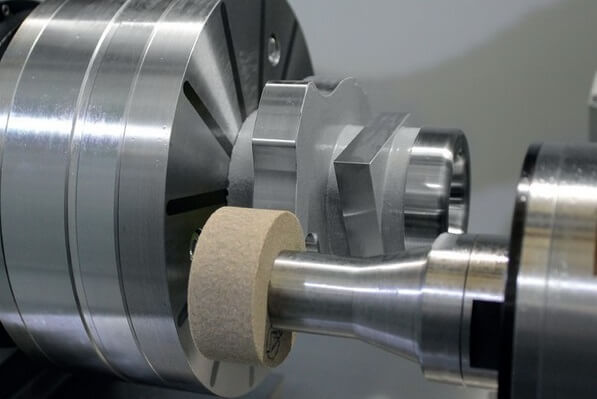

An external cylindrical grinder is a machine used to shape the outside surface of a cylindrical workpiece. The process involves rotating the workpiece while a grinding wheel removes material to achieve the desired size, finish, and tolerance. These machines are commonly used in industries such as automotive, aerospace, toolmaking, and manufacturing, where accuracy and surface quality are critical. External cylindrical grinders can be operated manually or through CNC systems, each offering distinct advantages and limitations.

Manual External Cylindrical Grinders

Manual grinders have been in use for decades and remain an essential tool in many workshops. They rely heavily on the operator’s skill and experience to achieve accurate results.

Features of Manual Grinders

- Operated using handwheels and levers

- Suitable for simpler geometries and small batch production

- Requires skilled machinists for precision outcomes

- Typically lower initial investment compared to CNC grinders

Advantages of Manual Grinders

- Lower Cost: Manual machines are generally more affordable upfront, making them a suitable choice for small workshops or businesses with limited budgets.

- Flexibility in Custom Work: Skilled machinists can quickly set up manual grinders for unique, one-off jobs.

- Simplicity: With fewer electronic systems, maintenance is straightforward and downtime is often minimal.

- Training Value: Ideal for teaching fundamentals of grinding and machining to apprentices and new operators.

Limitations of Manual Grinders

- Operator Dependency: Accuracy depends on the machinist’s skill, making it difficult to achieve consistent results.

- Time-Consuming: Manual setups and adjustments can be slow, limiting productivity for larger batches.

- Limited Complexity: Not ideal for intricate shapes or advanced geometries.

- Fatigue and Human Error: Extended operation increases the risk of mistakes and inconsistency.

CNC External Cylindrical Grinders

CNC grinders represent the modern evolution of machining technology. These machines use computer-controlled programming to perform highly precise grinding operations with minimal human intervention.

Features of CNC Grinders

- Automated control using G-code programming

- Capable of multi-axis operations for complex geometries

- High repeatability and precision within tight tolerances

- Equipped with advanced software for simulation and error detection

Advantages of CNC Grinders

- Superior Accuracy: CNC systems ensure consistent precision, even across large production volumes.

- High Efficiency: Automated operations allow for faster cycle times and increased throughput.

- Complex Geometries: Easily handles intricate shapes, tapers, and profiles that would be challenging manually.

- Reduced Human Error: Automation minimizes mistakes caused by operator fatigue or inexperience.

- Scalability: Ideal for mass production and industries requiring uniform quality.

- Advanced Features: Integration of sensors, real-time monitoring, and automatic wheel dressing enhance performance and reduce downtime.

Limitations of CNC Grinders

- Higher Investment: Initial purchase and setup costs are significantly greater than manual machines.

- Training Requirement: Operators must learn CNC programming and software, which requires time and resources.

- Maintenance Complexity: Repairs and servicing often require specialized technicians and parts.

- Not Always Cost-Effective for Small Jobs: For one-off or very small batch production, the setup time may outweigh the benefits.

Key Factors to Consider When Choosing

Choosing between a manual and CNC external cylindrical grinder involves assessing your specific needs and constraints.

Production Volume

If your operations involve high-volume production runs, CNC grinders are the clear choice due to their speed, efficiency, and repeatability. For small batch or prototype work, manual grinders may still be practical and economical.

Complexity of Workpieces

Workpieces with intricate shapes, tight tolerances, or advanced geometries benefit from CNC technology. Manual grinders are better suited for simpler cylindrical forms or jobs where customization is required without extensive programming.

Budget and Investment

Manual machines are more affordable upfront and easier to maintain, while CNC grinders demand a larger initial investment. However, the long-term efficiency and reduced waste of CNC machines can justify the cost for businesses focusing on large-scale operations.

Skill and Workforce

A manual grinder requires an experienced machinist for consistent results, while CNC grinders reduce dependency on operator expertise. If your workforce lacks highly skilled machinists, investing in CNC technology may minimize errors and training costs.

Flexibility and Adaptability

For workshops handling diverse jobs in small quantities, manual grinders provide greater flexibility. CNC grinders, on the other hand, are excellent for standardized production where uniformity is critical.

Industry Applications

Manual Grinder Applications

- Custom toolmaking

- Small repair shops

- Low-volume production

- Educational institutions teaching machining basics

CNC Grinder Applications

- Automotive industry for high-precision engine parts

- Aerospace for tight-tolerance components

- Medical device manufacturing requiring flawless finishes

- Large-scale industrial production where uniformity is essential

Balancing Manual and CNC Solutions

Some businesses may find that a combination of both manual and CNC external cylindrical grinders provides the most versatility. Manual machines can handle quick, simple, or custom jobs, while CNC grinders manage high-volume or complex production. This hybrid approach allows companies to maximize efficiency while keeping costs under control.

The Future of External Cylindrical Grinding

Advancements in automation, artificial intelligence, and smart manufacturing are pushing CNC grinders toward even greater efficiency and precision. Features like predictive maintenance, machine learning optimization, and real-time data monitoring are already reshaping the landscape. While manual grinders will continue to play a role in niche applications and training, CNC grinders are set to dominate industries requiring scalable, consistent, and complex machining solutions.

Conclusion

Selecting the right external cylindrical grinder comes down to understanding your production demands, budget, and workforce capabilities. Manual grinders offer affordability, simplicity, and flexibility for small-scale operations, while CNC grinders deliver speed, precision, and efficiency for larger, more complex tasks. For many businesses, the decision is not about choosing one over the other but finding the right balance between manual craftsmanship and CNC automation. Ultimately, the right choice is the one that aligns with your goals for productivity, accuracy, and long-term growth.